As the traditional manufacturing industry, mining enterprises mainly use iron ores as raw materials. Differences in domestic geological features and sorting techniques make the daily processing volume of raw materials relatively large. Moreover, the logistics links of production, supply and sales are closely connected between upstream and downstream. Therefore, the logistics in mining enterprises is the economic lifeline of the entire mining enterprise. Therefore, strengthening the intelligent logistics management is of great significance for the intelligent development of mining enterprises. Especially currently with the rapid development of logistics modernization, the development level of logistics intelligence in mining enterprises has reached to a certain extent, representing the development level of intelligent mine construction.

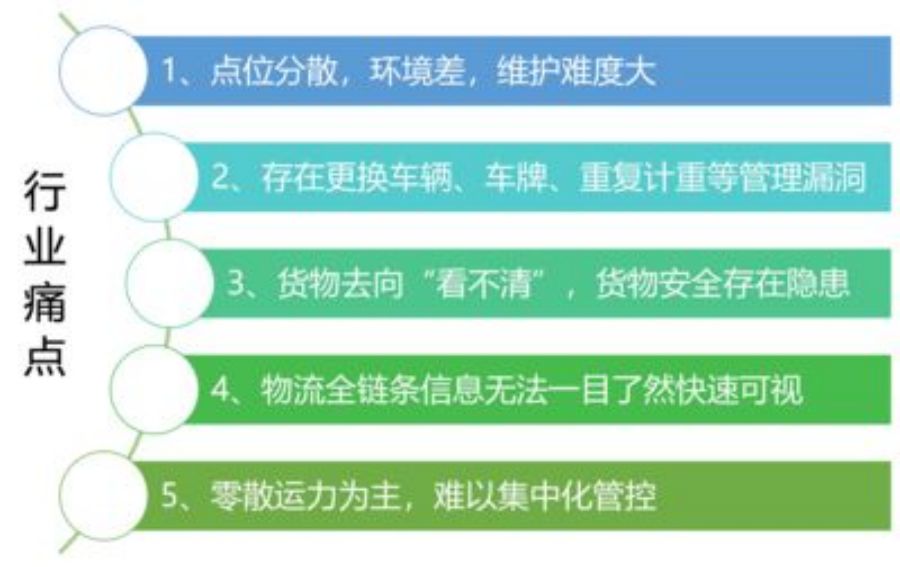

In recent years, with the introduction of logistics 4.0 and the rapid development of social logistics, mining enterprises have become more and more aware of the loopholes and pain points in their own logistics management, which have brought great hidden dangers and risk to resource management and production and operation. Therefore, constructing enterprise logistics management and control platform has become the development trend in mining enterprise logistics management.

Effects Solidify the logistics management process and standardize the logistics management business. The transition from human defense to technical defense reduces management risks and plugs management loopholes. The quality data cannot be changed which is seamlessly connected with the financial system. The intelligent logistics development has driven the improvement of the overall intelligence level. Benefits Reduce personnel participation and reduce labor costs. Eliminate fraudulent behaviors such as lost goods and one vehicle of materials weighing repeated, and reduce losses. Improve operation and maintenance efficiency and reduce operation and maintenance costs.

Big data processing platform: logistics information such as logistics dynamics, weighbridge operation, etc. is clear at a glance.

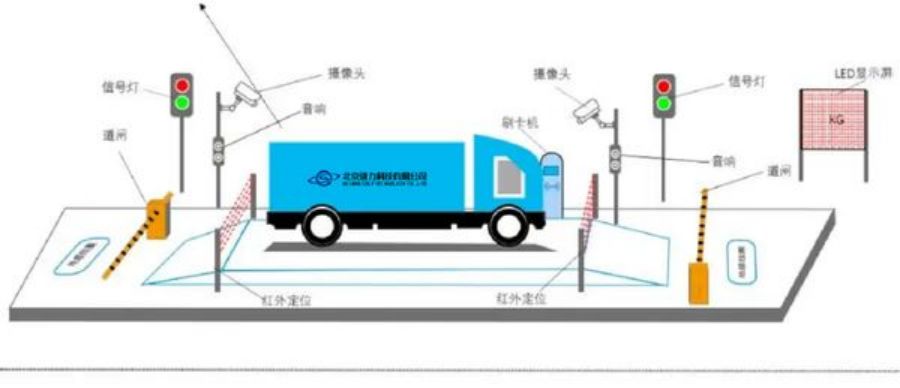

Big data processing platform: logistics information such as logistics dynamics, weighbridge operation, etc. is clear at a glance. Unattended weighing system: The system supports multi-media such as IC card, vehicle number identification, RFID, etc., and various application scenarios such as weighing with drivers getting off or not getting off the vehicle, and early warning of various special situations such as overweight and overload management and control, sold quantities being over-provisioned management and control, and the original purchased raw materials.

Unattended weighing system: The system supports multi-media such as IC card, vehicle number identification, RFID, etc., and various application scenarios such as weighing with drivers getting off or not getting off the vehicle, and early warning of various special situations such as overweight and overload management and control, sold quantities being over-provisioned management and control, and the original purchased raw materials. Financial settlement: directly connect with the financial system, and the data is synchronized with the financial system in real time. Contract settlement and pricing management can also be performed based on measurement and laboratory data.

Financial settlement: directly connect with the financial system, and the data is synchronized with the financial system in real time. Contract settlement and pricing management can also be performed based on measurement and laboratory data. Mobile APP: Through the application of cloud platform + metering APP, managers can conduct customer management, dispatching management, real-time data query, and abnormal reminders through mobile terminals.

Mobile APP: Through the application of cloud platform + metering APP, managers can conduct customer management, dispatching management, real-time data query, and abnormal reminders through mobile terminals.