The solution for MES provides enterprises with an effective way that can realize transparent management in the production process. It is an information management system with production management as the core, helping enterprises to establish an integrated and transparent production site process control management platform, and to build a complete production process database which can real-time monitoring and comprehensive traceability in the production process, and continuously improve product output and quality through statistical analysis of data, so as to continuously improve market influence.

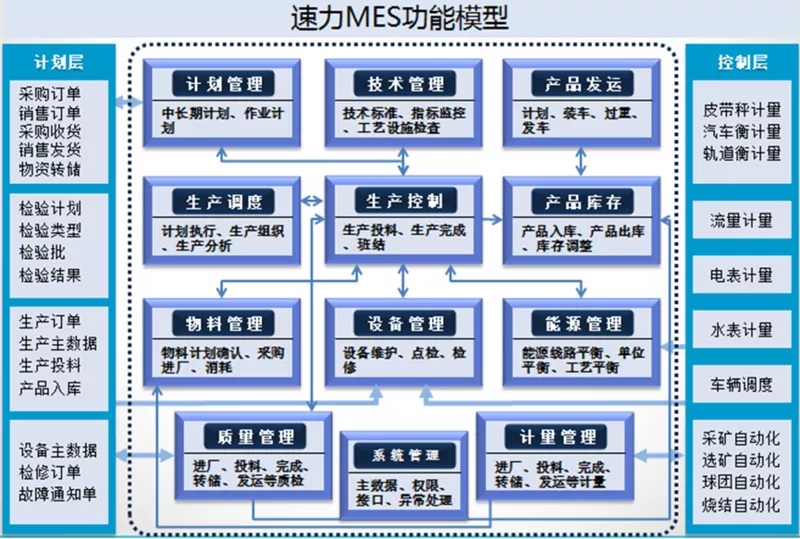

The solution for MES provides enterprises with an effective way that can realize transparent management in the production process. It is an information management system with production management as the core, helping enterprises to establish an integrated and transparent production site process control management platform, and to build a complete production process database which can real-time monitoring and comprehensive traceability in the production process, and continuously improve product output and quality through statistical analysis of data, so as to continuously improve market influence. Taking production process as the principal line, based on real-time industrial data such as automation, measurement, and energy; MES runs through professional management process such as production, quality, scheduling, equipment, technology, procurement, sales, and energy, covers twelve functional modules, that is management, technical management, production shipping, production scheduling, production control, product inventory, material management, equipment management, energy management, quality management, measurement management, system management.

Taking production process as the principal line, based on real-time industrial data such as automation, measurement, and energy; MES runs through professional management process such as production, quality, scheduling, equipment, technology, procurement, sales, and energy, covers twelve functional modules, that is management, technical management, production shipping, production scheduling, production control, product inventory, material management, equipment management, energy management, quality management, measurement management, system management. The main management effects are as follows: The management level has been significant improved. Strengthen centralized management, form a collaborative mechanism, and promote collaborative management Weaken functional management and strengthen process management. Promote standardized management and improve execution. Promote refined management and strengthen management intensity. Improve management transparency and increase management binding. The management efficiency has been significant improved The system can reflect production, measurement, quality, logistics and other data timely and dynamically, and can be queried and applied at any time. Data and information are got from the lowest level of measurement, quality inspection, equipment acquisition or automatically generated by the system, which is timely and accurate. Leaders and managers at all levels are freed from a large number of repetitive tasks with low management content. In the past, work that required manual methods and took a lot of manpower and time is now transformed into simple and short-lived work with the help of information technology, and the work efficiency has been improved hundreds of times. Management foundation has been strengthened Provide true and accurate data. From manual input to direct collecting from automated instruments and meters into the secondary database for processing and sorting, the data is transparent whose authenticity can be guaranteed. Accelerate data analysis and response. The system automatically forms a visual report board, which can make you pays attention to the real-time production situation on site in real time at any places.

The main management effects are as follows: The management level has been significant improved. Strengthen centralized management, form a collaborative mechanism, and promote collaborative management Weaken functional management and strengthen process management. Promote standardized management and improve execution. Promote refined management and strengthen management intensity. Improve management transparency and increase management binding. The management efficiency has been significant improved The system can reflect production, measurement, quality, logistics and other data timely and dynamically, and can be queried and applied at any time. Data and information are got from the lowest level of measurement, quality inspection, equipment acquisition or automatically generated by the system, which is timely and accurate. Leaders and managers at all levels are freed from a large number of repetitive tasks with low management content. In the past, work that required manual methods and took a lot of manpower and time is now transformed into simple and short-lived work with the help of information technology, and the work efficiency has been improved hundreds of times. Management foundation has been strengthened Provide true and accurate data. From manual input to direct collecting from automated instruments and meters into the secondary database for processing and sorting, the data is transparent whose authenticity can be guaranteed. Accelerate data analysis and response. The system automatically forms a visual report board, which can make you pays attention to the real-time production situation on site in real time at any places.