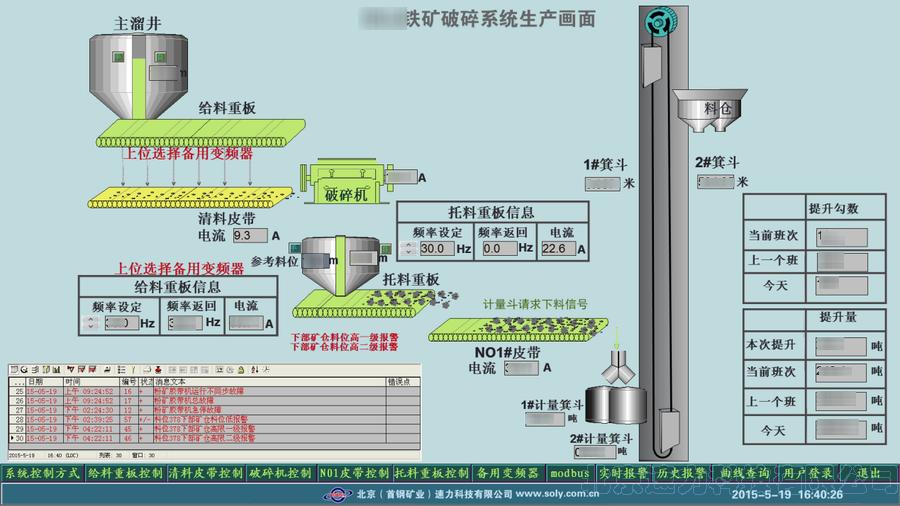

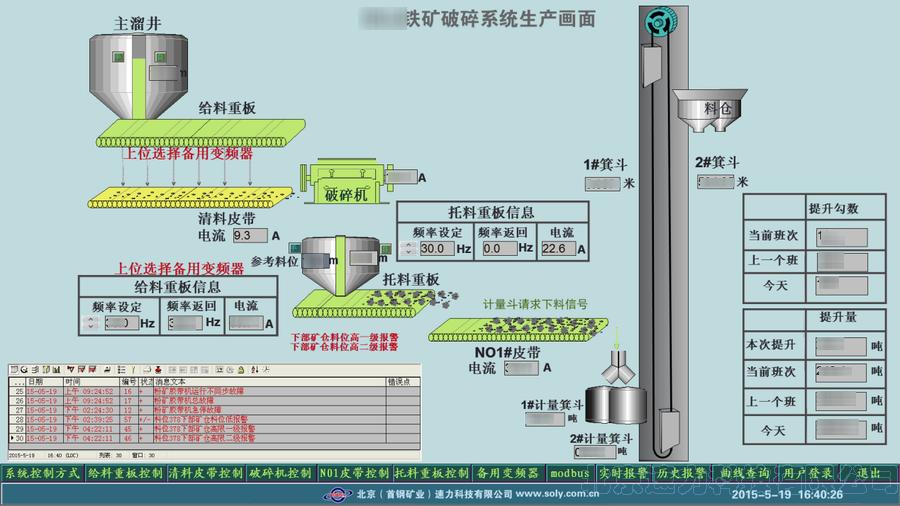

The control station is equipped with a PLC control system, which is responsible for controlling and managing the heavy-duty plate feeder, crusher, feeder, belt conveyor and other equipment of the crushing system. It is connected with the main control (dispatching) system through redundant Ethernet to accept the operation instructions from the main control room. The upper part of the ore bin has the material level alarm and interlock control function; the motor running states of electrical equipment such as the crusher are monitored, and the interlock control is automatically started and stopped. The lower part of ore bin has functions of level indication, recording, alarm and interlock. The motor running states of electrical equipment such as the conveyor are monitored, and the interlock control is automatically started and stopped. It can indicate and record the dust concentration at the inlet and outlet of the dust collector, and alarm the high and low material levels of the dust collector. At the same time, it can set up the necessary signal systems such as start and stop warning signals, equipment operation status signals, production contact signals, and accident signals.Realize unattended underground crushing system;

Achieve seamless link with the main shaft lift.

Seamlessly link with the main shaft lifting to complete the production interlocking;

Intelligent crushing operation mode to improve production management efficiency;

High-precision material level detection ensures smooth and stable production;

Friendly interface, simple operation, and one-key start and stop for production.