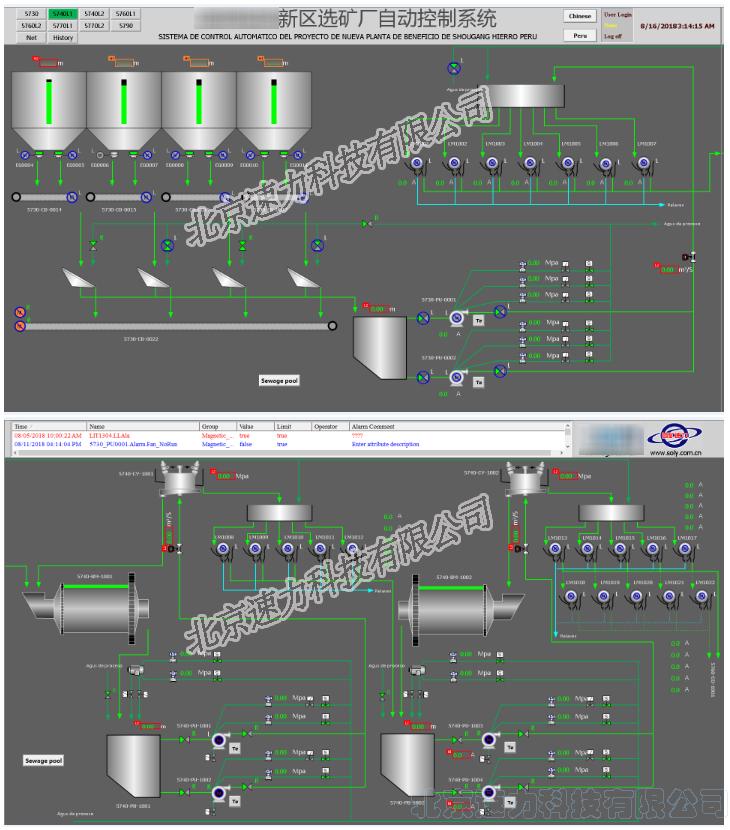

The intelligent grinding and separation control system stabilizes the grinding process flow, and stabilizes the machine-hour processing capacity of the grinding equipment on the basis of ensuring that the grinding products meet the separation indicators. Automatic interlocking control and state monitoring of the entire process equipment and corresponding water volume and concentration control.

In the grinding system, manually judge the mill load to adjust the feeder operation status. Due to the untimely adjustment and unstable operation, the mill often has the phenomenon of "empty stomach" or "swelling stomach", which affects the quality of the entire grinding process.

Stage1 grinding is the entrance of the grinding process. The machine-hour processing capacity in stage1 grinding station represents the processing capacity of the grinding process. If the product quality is qualified and the subsequent process allows, increasing the process processing capacity will bring more benefits. Therefore, the stability of stage1 grinding control is the most critical factor in the control of the grinding process.

Through the intelligent ball-milling control system to stabilize the grinding process flow, fuzzily control the process water supply and ore feeding ratio adjustment, on the basis of ensuring that the grinding products meet the separation indicators, the machine-our processing capacity of the grinding process can be stabilized and the equipment operation status can be monitored.