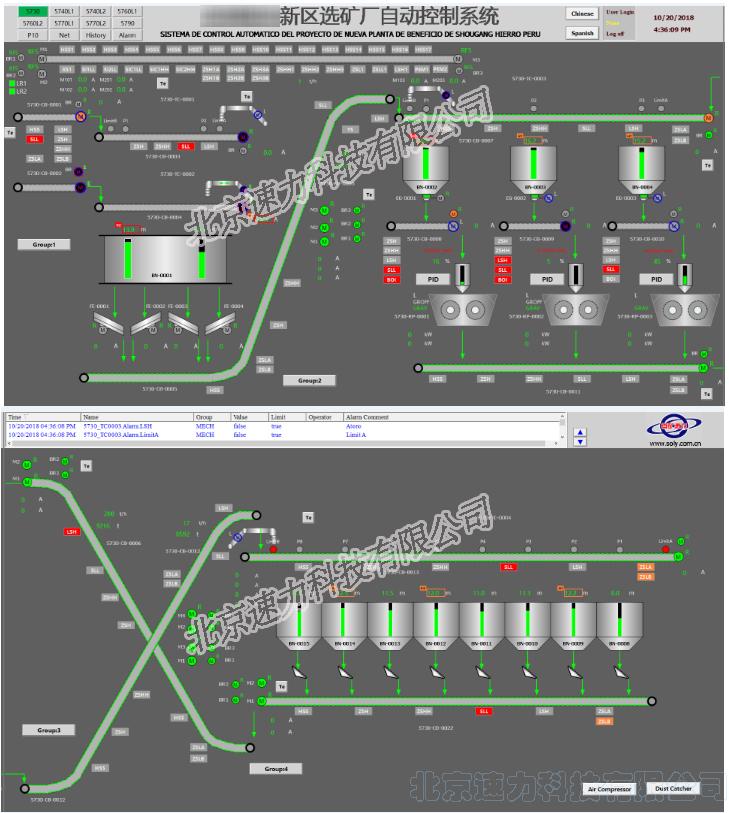

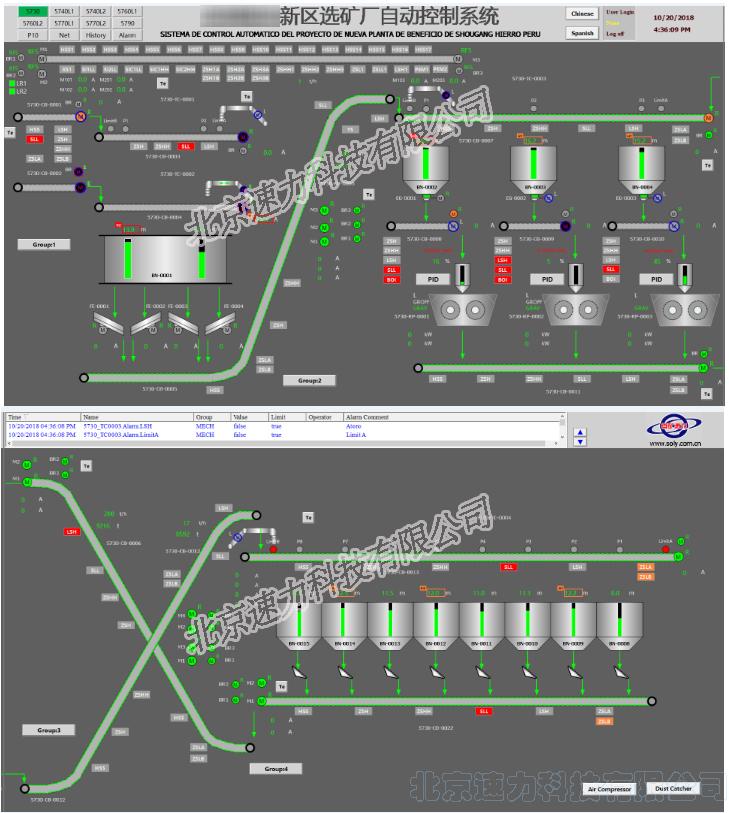

According to the actual situation of the crushing system process, combined with the idea of "creating first-class belt management" of the company, the crushing control system takes "simplicity, safety, practicality and reliability" as the principle, and takes eliminating the belt guarding post as the goal, and integrates belts into the centralized-control system. The main control system collects manual and automatic operation signals, overheating signals, current signals, belt off-tracking and under-speed signals, rope-pulling signal and others, realizes interlocking control of the whole process. The system can remotely control the feeding trolley at the control center to exempt workers from exposing in the dusty site. The crusher can realize constant power control. the system real time monitors production process parameters, real time uploads equipment running status and parameters (such as motor running current, the oil pressure of lubrication system, oil temperature, belt slip, off tracking, existence of iron, etc.), and participate in the system operation interlock, protect the safe operation of the equipment, and avoid emergency shutdown. The safe startup conditions of important equipment, such as cone crushing equipment involves in system start-stop interlock. The emergency stop signal is used as the interlock condition of starting the system, and the system starts in inverse process and stop in forward process. If there is a fault shutdown, stop equipment according to the pre-scheduled shutdown mode, preventing further expansion of the fault. The core concept of intelligent crushing system control Monitoring and timely adjusting three - level throats;

Effectively increase the throughput of the crushing grating, which is conducive to reducing the running time of the crushing system, improving the through capacity of the fine crushing system, and effectively reducing the unit consumption of crushing;

Tap the potential of the crusher efficiency, monitor and reasonably control crushing cycle load, optimize the size composition of the final product of crushing, effectively improve crushing fineness, realize the constant power control of the fine crushing machine, which is conducive to improving the size composition. The improvement of the particle size of crushing is conducive to improving the working ability in the next process (the machine-hour capacity of the ball mill), so as to achieve the goal of "more crushing and less grinding".

Equipment interlock protection system, belt system protection, crusher protection and other related equipment protection system can efficiently, orderly, intensively start and stop system.